Delivered early October 2020 to distributor Tutt Bryant Equipment’s Rocklea site in Queensland, the mobile scalping screen is the first of its kind on the continent.

Tutt Bryant Equipment recently sold the machine, which can be off the float and operational within just 20 minutes, to a large coal mining contractor going straight to work on a central Queensland coal mine. The customer also purchased a Nordtrack CT100 mobile conveyor to support the S2.11 by providing a very large stockpile of material.

The Nordtrack range is especially ideal for contractors, with high mobility between job sites, compact size for ease of use, plus rapid delivery times. The units come in standard configurations for asphalt recycling, separating organic materials and aggregate production. The attractive price point and ease of use also suits those who are just starting their own operations.

Dependable distributor, reliable equipment

Tutt Bryant Equipment’s Crushing and Screening Account Manager, Darrell Porter, has been in discussions with the customer’s site operations staff since 2018 and was the customer’s first port of call when this project came to fruition.

“The Metso Outotec difference is the depth of technical information to support the equipment selection for the application,” said Porter about the large volume of information he provided to the customer to assist their decision-making process.

In light of COVID-19’s impact on work and production schedules globally, the machines were still delivered in a reasonable timeframe from their Metso Outotec production facilities. Tutt Bryant Equipment utilised one of its hire fleet scalping screens while waiting for the delivery of the S2.11.

Just after the equipment arrived, the customer’s project manager was invited to Tutt Bryant Equipment’s Brisbane workshop to inspect the machines to ensure mine site compliance. A few small adjustments were made, which ensured the machines were passed in by the mine safety compliance team without issue.

Since the Nordtrack S2.11 and CT100 have been operational, the client gladly reports that they have been consistently achieving 20% over their required production target.

Made to make contracting more productive

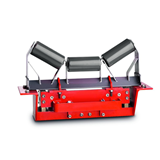

The Nordtrack S2.11 mobile scalping screen handles massive volumes of feed material with precision thanks to its robust structure, massive screenbox and powerful stockpiling conveyors. With the ability and availability of various different screening media, the unit is versatile for different applications from primary scalping to tertiary screening. The size, stockpile height and aftermarket support made this model the ideal screen choice for the customer.

The Nordtrack CT100 mobile conveyor is designed to carry heavy loads and can be easily relocated on a production site or transported between sites. Its structure and quality parts ensure high carry-over capacity, and the 31 meter (100 feet) long conveyor can create a 12-meter-high stockpile.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)