Many manufacturers do not even have a torque specification for each of their screw assemblies, let alone calibrate their screwdrivers. Some screwdrivers are easily adjusted by the production line workers, while others are simply not checked until something goes wrong (too late!!).

"As long as the screw is not stripped", "As long as a screw is there" are phrases our sales engineers often hear when they ask if there is a torque specification. Unfortunately that is not good enough these days. There is no way of knowing if a screw is stripped after assembly unless there is some kind of supervision system or the operators care enough to reject the part as it happens. Just because an inspector sees that all of the screws are assembled does not mean that they are all assembled to torque or not stripped. Testing every screw after assembly with a torque wrench is a waste of time and inaccurate.

Customers expect more from Australian manufactured goods. You can imagine the disappointment of a customer who has chosen Australian made products and finds that it is faulty because of something as simple as a stripped or loose screw? He would probably think he may as well have bought the Chinese product for a fraction of the price. What if that company was one of your main export customers?

What's the solution?

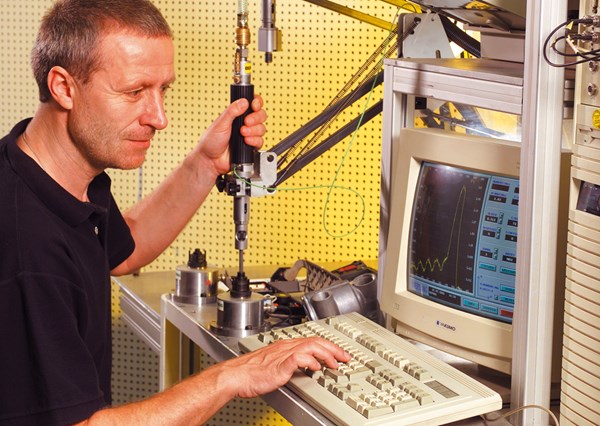

- Invest in some torque analysis equipment to first set a torque specification and then periodically check the joint and screwdriver. The most basic requirement for any serious manufacturer who uses screws, should be to have torque specifications and to regularly check the joint and screwdrivers.

- Only buy production quality screwdrivers. They are quieter, more ergonomic, last longer and are more accurate than cheap drivers. Check the accuracy of your screwdrivers using your torque analysis equipment. Check the torque on a hard and soft joint and compare the averages. If it's an air driver check the torque with high and low air pressure and compare the averages.

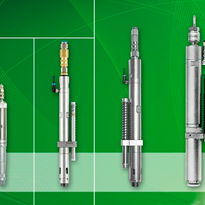

- Consider screwdrivers with supervisors to count the screws per part and check that torque has been reached on every screw. We can also supply position controlled equipment that monitors the position of the screwdriver and can even select different tightening strategies based on the screw position

- If the joint is important, consider screwdrivers that measure and document the torque for each screw – don't leave it up to the operator to tell you that there is a problem!!

We have over 20 years experience in helping customers with torque screwdriving productivity and quality control issues. Please don't hesitate to contact us with advice on your applications, contact Paul De Rossi.

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)