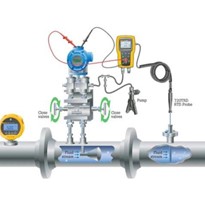

The use of the type 8098 FLOWave not only reduces the number of devices in a plant, but also reduces costs and effort in plant planning, installation, start-up and maintenance. Thanks to the well-thought-out device construction with only one line and seal, FLOWave is easy to clean and also requires fewer calibrations compared to similar products. The possible uses for FLOWave have now been expanded due to the additional measuring parameters of mass flow and density.

It is a compact solution: as a device for multiple measured quantities and applications the Type 8098 FLOWave can measure more than just flow. For example, the sensor recognises the change of liquids and gas bubbles in the medium. To do this, the device simultaneously records different measuring parameters and analyses them:

- Volume flow

- Temperature

- Acoustic transfer factor

- Differentiation factor

Usually multiple devices are required in order to monitor all these parameters. FLOWave combines these measured quantities in one device, and is also now in a position to determine other measured quantities.

New measured quantities of FLOWave

Density (in kg/l, g/cc etc.)

Density means the ratio of mass to volume. FLOWave determines density using the acoustic parameters of the liquid. The advantage is that the measured value can be directly included in the ongoing process at a set measurement point.

Mass flow (in t/h, kg/min, etc.)

Mass flow is a dynamic mass per time unit and is defined as the mass of a medium that is moved through a cross-section over a period of time. In measurements with surface acoustic wave (SAW) technology, which is also used in the FLOWave, the mass flow is calculated using the measured values of density and volume flow. In contrast, other measurement principles such as Coriolis use mass flow and density to deduce the volume flow.

These additional measured quantities are available for new FLOWave devices and can be added when purchasing, depending on requirements. Users can decide for themselves which functions they really want to use. For devices that have already been commissioned, it is unfortunately not possible to activate the additional measured values due to technical differences, as these may impact measurement accuracy.

Additional functions open up other areas of use

FLOWave has been used in a wide variety of processes since 2015 and will support users with flow measurements of all kinds, with its advantages being of particular use in the pharmaceutical and food and beverage industries. Due to the new measured quantities, the Type 8098 can be used in the following applications, for example:

- Measuring the flow of cooking oil

- Measuring the mass flow of liquids in pharmaceutical applications

- Blending and mixing alcoholic and non-alcoholic beverages

Benefits at a glance

- A device for multiple measured quantities ensures low installation costs and time-saving device management.

- Permanently stable process values, no losses of pressure and easy cleaning due to well-thought-out device construction.

- Seamless process monitoring enables quick action in the event of faults, such as changes to the liquid.

- IP65 degree of protection, ATEX, IECEx or CRN for use in demanding environments.

- Hygienic stainless steel device design.

-160x160-state_article-rel-cat.png)