As industries strive for higher efficiency, precision, and productivity, the integration of advanced robotics in structural steel assembly is becoming increasingly prevalent. This blog explores the latest trends in robotic fitting and welding and highlights how AGEN Robotic Structural Steel Assembly is revolutionising traditional workshops into state-of-the-art factories of the future.

TRENDS IN ROBOTIC FITTING AND WELDING

Increased Automation - One of the most significant trends in robotic fitting and welding is the push towards full automation. Robots are now capable of handling more complex tasks with minimal human intervention. This shift not only increases productivity but also ensures consistent quality and reduces the risk of errors.

Advanced Sensing and Adaptive Control - Modern robotic systems are equipped with advanced sensors and adaptive control technologies. These capabilities enable robots to adjust in real time to variations in the workpiece and welding conditions, ensuring optimal performance and quality.

Collaborative Robots (Cobots) - Collaborative robots, or cobots, are designed to work alongside human operators. They are enhancing efficiency by combining the precision of robotics with human dexterity and decision-making skills. Cobots are becoming more common in workshops, allowing for a seamless integration of robotic and human labour.

Integration with IoT and Data Analytics - The Internet of Things (IoT) and data analytics are playing a crucial role in robotic fitting and welding. IoT-enabled robots can communicate and coordinate with other machines and systems, providing valuable data that can be analysed to optimise processes and predict maintenance needs.

Artificial Intelligence and Machine Learning - AI and machine learning are being integrated into robotic systems to enhance their capabilities. These technologies enable robots to learn from previous tasks, improve their performance over time, and even make autonomous decisions based on the data they collect.

HOW AGEN RSSA IS LEADING THE CHANGE

AGEN Robotic Structural Steel Assembly is at the cutting edge of these trends, offering solutions that transform traditional workshops into highly efficient and modern factories. Here’s how:

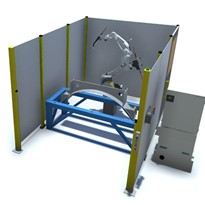

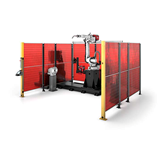

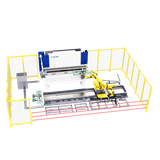

- Comprehensive Automation Solutions - AGEN provides comprehensive automation systems that cover the entire spectrum of structural steel assembly. Their robotic systems are designed to automate fitting, welding, and other critical processes, ensuring maximum efficiency and precision.

- State-of-the-Art Robotics - With advanced robotics equipped with the latest sensors and adaptive control technologies, AGEN’s systems ensure consistent high-quality output. Their robots can handle complex geometries and variations, making them ideal for a wide range of applications.

- Collaborative Capabilities - AGEN’s cobots are designed to work in tandem with human operators, enhancing productivity and safety in the workshop. These robots are easy to program and can be quickly adapted to different tasks, providing flexibility and scalability.

- IoT and Data-Driven Insights - By integrating IoT and data analytics, AGEN’s robotic systems provide real-time insights into the manufacturing process. This data can be used to optimise operations, reduce downtime, and improve overall efficiency.

- AI-Enhanced Performance - AGEN leverages AI and machine learning to enhance the performance of its robotic systems. Their robots can learn and adapt to new challenges, continually improving their efficiency and effectiveness.

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)