This is regarding a vane type pump but some of the system solutions are across all other pump types.

Him: Hi Rod. Its XXXXXX here from XXXXXXXX-XXX septics services. My pump wont suck. It used to fill the truck in 12 minutes but now its takes 45 minutes or longer.

Rod: G’day XXXXXX. Long time no hear. Geez that’s no good XXXXXX, have you checked the suction hose to see it’s not blocked?

Him: Yep, not only but also took off the pump and replaced the vanes and also all of the hoses between the vac pump and PSO/SSO as well

Rod: Mmmm in doing that you’ve covered a lot of my next lot of questions (see further explanations below) did you check or replace the check ball in the non-return valve of the vac pump?

Him: Yep, oiled it as well.

Rod: Hmmm, (oiled balls?) Did you check that the ball rubber was hard and not soft?

Him: Why?

Rod: If the ball rubber covering is starting to delaminate, I suggest that it will be deforming under vacuum and block the inlet port which will severely limit vacuum. It will also cause the pump to run extremely hot and heat up very quickly as well as the pump is essentially running at full vacuum straight away.

Him: Nope haven’t checked for that but I will do so and let you know how I get on.

Rod: Righto, cop u later!

Him: Thanks, Hooroo!

More stuff to think about in relation to no or little vacuum. Further points for consideration:

- Check the vacuum system hoses from the vac pump to the vac tank. In some cases these hoses can internally delaminate under vacuum and it is impossible to see. To check this completely replace the hoses from the tank to PSO to SSO to final filter to vac pump with a standard suction hose and then run the unit. If the hoses had been delaminating then the vac pump will heat up quickly and the tank will promptly run out of vacuum.

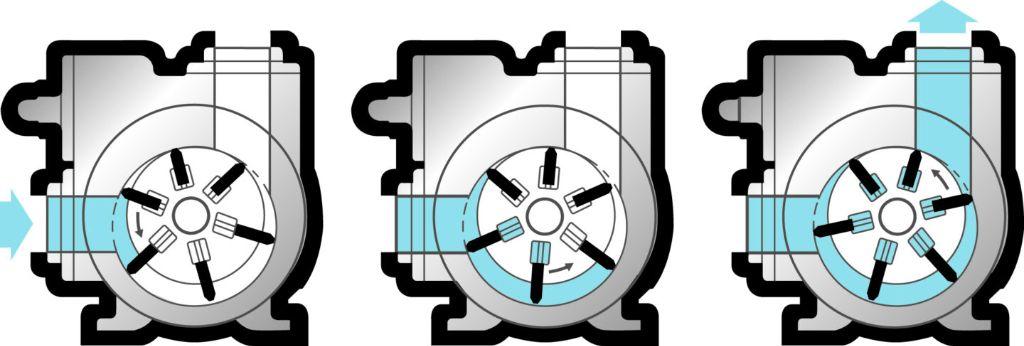

- If a vane pump check that the vanes are dropping out freely from the rotor, this may necessitate removing an endplate to verify. If not then remove the vanes and thoroughly clean the rotor slots and inspect the vanes for splitting and any other issues which may cause them not to drop freely. If the vanes drop freely, coat the vanes with pump oil and reinstall them. If they still don’t drop freely then they may have warped. Its possible to straighten the vanes by wrapping them in a soft cloth and putting them in a vice without over-tightening and twist the other end of the vane in the direction it needs to go in order to straighten. If this still doesn’t fix the issue replaces the vanes.

- Check the pump rotation speed at full load. Ideally the pump should be at its correct speed. In the case of the offending pump, it should have been 900-1000rpm. A small hand held digital tach is a very handy inexpensive piece of kit.

- Check that the waste inlet port is free of obstructions. Likewise check that the waste suction hose is also free of obstructions.

- If there is a final filter present, are the elements clean and free of contaminants? If not clean or replace.

- A stupid one but is the SSO empty? If its near full the ball will pick up and block vacuum almost immediately.

- Once, we had a customer phone up in a hell of a flap. “this new bloody truck is no good, it wont suck!!! Me: why? It worked very well yesterday but now its no good! Me: what’s different? We washed it out yesterday and today its not sucking. Me: have you checked that all the manways are closed? No why should I should I? Me: some times operators will not close them thoroughly. Don’t be stupid our operators are top notch…. Oh shit the manway is bloody well open. Click, buzzzzzz.

- Is the waste suction hose stuck to the bottom of the tank?

- Check for any suction leaks. Is the vac relief set?

- Reset if needed.

- Is the airflow valve handle in the correct position?